6 Innovative Uses of Data Loggers in Industrial Settings

Ever heard of a tiny device that can be your secret weapon for industrial success? Believe it or not, that's exactly what a data logger is! These unsung heroes might not be the flashiest pieces of equipment, but they pack a powerful punch when it comes to monitoring, analysing, and optimising industrial processes.

In this post, we'll dive into six innovative ways data loggers are revolutionizing the way things are done in factories, warehouses, and production lines across the globe. So, buckle up and get ready to discover how these little gadgets can make a big difference!

Maintaining Perfect Conditions: Environmental Monitoring

Imagine a world where temperature fluctuations ruin delicate materials, or humidity levels disrupt sensitive equipment. Yikes! Thankfully, data loggers come to the rescue. By constantly tracking temperature, humidity, pressure, and other environmental factors, they ensure your workspace stays within the perfect zone. This is crucial for industries like food processing, pharmaceuticals, and electronics manufacturing, where maintaining specific conditions is paramount for quality control.

For instance, a bakery might use a data logger to monitor the temperature and humidity of their proofing rooms, where the dough rises before baking. This ensures consistent results and prevents batches from being ruined due to temperature fluctuations.

Data loggers can also be equipped with alarms that trigger if readings go outside the desired range. This allows for immediate intervention and prevents costly product spoilage or equipment damage.

Optimising Energy Consumption: Becoming Eco-Friendly and Cost-Conscious

Are energy bills eating into your profits? Data loggers can be your secret weapon in the fight against rising costs. By tracking energy consumption patterns of equipment and machinery, they help identify areas for improvement. Imagine a data logger monitoring the energy use of a factory's air conditioning system. By analysing the data, you might discover times when the system is running unnecessarily, leading to adjustments and significant energy savings.

Furthermore, data loggers can help businesses comply with environmental regulations and sustainability goals. By monitoring energy usage and identifying areas for efficiency, companies can reduce their carbon footprint and contribute to a greener future.

Predictive Maintenance: Preventing Problems Before They Arise

Imagine a scenario where a critical piece of machinery suddenly breaks down, halting production and causing costly delays. Yikes again! Predictive maintenance, powered by data loggers, can help turn this nightmare into a distant memory.

By continuously monitoring vibration, temperature, and other parameters of equipment, data loggers can identify subtle changes that might indicate potential problems. Think of it as having a tiny stethoscope for your machines! Early detection allows for preventative maintenance, avoiding catastrophic breakdowns and keeping production lines humming smoothly.

For example, a data logger might detect abnormal vibrations in a motor, signalling potential bearing wear. By addressing this issue early on, the company can avoid a complete motor failure and the associated downtime and repair costs.

Ensuring Cold Chain Integrity: Keeping Perishables Fresh

For industries that deal with perishable goods, maintaining a constant cold chain is crucial. This refers to the uninterrupted temperature-controlled storage and transportation of products like food, pharmaceuticals, and even vaccines. Even slight temperature fluctuations can compromise the safety and quality of these products.

Data loggers play a vital role in ensuring cold chain integrity. They continuously monitor temperature throughout the entire supply chain, from storage facilities to transportation vehicles. This data allows companies to identify any breaches in the cold chain and take corrective action to protect their products.

Imagine a shipment of life-saving vaccines being monitored by a data logger. By tracking the temperature throughout the journey, healthcare providers can ensure the vaccines remain potent and effective upon arrival.

Streamlining Logistics and Warehousing: Optimising Space and Operations

Warehousing and logistics are all about efficiency. Every inch of space counts, and every movement needs to be optimised. Data loggers can be a game-changer in this area.

By tracking the location and movement of inventory within a warehouse, data loggers help businesses optimise storage space and pick-and-pack operations. This can involve strategically placing high-demand items for easier access or identifying areas for improved organisation.

Furthermore, data loggers can be used to monitor environmental conditions within the warehouse, ensuring optimal storage conditions for different types of products. This not only prevents spoilage but also extends the shelf life of inventory.

Remote Monitoring: Peace of Mind from Anywhere

Imagine being able to monitor your entire industrial operation from the comfort of your own home (or even a beach vacation!). That's the power of remote monitoring with data loggers.

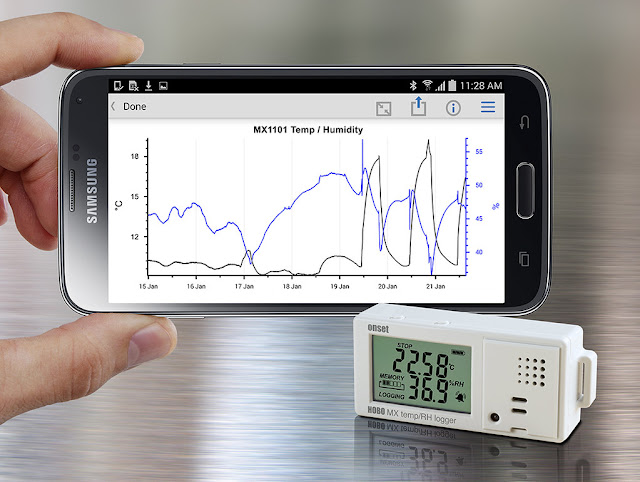

By connecting to the cloud or a central server, a data logger transmits data wirelessly, allowing for real-time monitoring from any location with an internet connection.

Conclusion

Data loggers might be small, but their impact on industrial settings is undeniable. By providing real-time, accurate data, they empower businesses to make informed decisions, improve efficiency, and ensure quality.

As technology advances, we can expect data loggers to play an even bigger role in shaping the future of industry.

Comments

Post a Comment